Sail Construction Details

Thank you for your interest in our offshore cruising sails!

Classic Mainsails

In-Mast Furling Sails

Roller Furling Sails

Hanked-on Headsails

Storm Headsails

Trys’ls

SpinDrifter

Drifter

All Sails

All sails are custom constructions based on the dimensions of your properly tuned rig, the displacement of your boat, and your sailing plans and experience.

-

Computer aided design using Autometrix SMSW software: sails are designed in house then double checked by world-renowned sail designer Sandy Goodall.

-

Entire sail construction happens in-house: nothing outsourced

-

Highest quality materials available

-

White Dacron— Contender Premium Low Aspect Fibercon

-

Classic mainsails, classic mizzens, hanked-on jibs and staysails, hanked-on storm jibs and staysails, trysails

-

White Dacron— Contender Premium Low Aspect Fibercon

-

Roller furling headsails, in-mast furling mainsails, in-boom furling mainsail

-

Tanbark or Cream Dacron cloth: manufacturer depends on customer’s color preference (Contender or Dimension Polyant APUV)—tanbark and cream Dacron are more expensive and will be listed as an option if requested.

-

Nylon sails – Contender Nylite in various weights

-

All cloth inspected before being cut on our in-house plotter/cutter

-

Wide seams accommodate three lines of stitch and allow for future re-stitching between original lines of stitch

-

Patch edges are folded

-

Leather chafe protection standard on all sails

-

Designed with self-sufficiency in mind

-

All hardware meets or exceeds specs for safe working load

-

Scrap fabric provided with all new sails (cloth for possible future repairs or color matching)

-

Jammer cleats and pockets for leech and foot lines

-

Primary rings are stainless steel hydraulically pressed super rings

-

Secondary rings are all hand-sewn

-

All rings placed for optimal load displacement

-

Nylon Sail Bag and Dacron sail ties included with each sail

Please be aware that new genoas or jibs often need chafe patches where spreaders and Raydomes contact the sail. These patches are not included in the original price of the sail because it won’t be clear whether they are needed or how big they might need to be until the sail is bent-on. After your sail is bent-on, we will help assess the need for patches free of charge. If you plan to sail locally for a season, we encourage you to sail awhile with the new sail “as is” then bring it back for chafe protection when chafe marks become visible.

Numbers, Logos, Insignias: Numbers, logos, and insignias are not required on cruising sails and are not included in the cost of our sails. Please feel free to request an estimate if you wish to add these items.

Classic Mainsails

Your mainsail is your most important sail; it will be used under most conditions during your passage-making and gunkholing experiences. Your Port Townsend Sails main will be well cut, durable, and adaptable to a wide range of voyaging conditions. In addition to the construction details described under “All Sails”, your classic mainsail will have the following specific construction details:

- Cross cut

- 2-ply leech

- Full reef bands with hand-sewn rings and two layers of reinforcement

- Batten pockets folded with a platform the length of the batten and chafe protection at both ends

- Webbing strainers in reef clew rings

- Webbing handles at reef tacks that aid in pulling the sail down when reefing or striking sail

- Loose footed (unless otherwise determined)

- Extra chafe protection at head and below second reef on leech

- Tapered/rat-tailed bolt rope extends around headboard and around tack

- External rope for chafe guard on luff

- EZ Reefs at reef tacks

- Luff slides webbed on and hand stitched

- Cunningham for sail trim

- Double slides at headboard (and clew if sail is not loose footed)

- High load slides added above reefs, at head, and at tack

- Clew strop

- Full Batten pockets thru-bolted at leech

Areas of your mainsail that might get chafed by shrouds, spreaders, and other rigging cannot be precisely known until the sail is bent-on and marked. Any chafe patches must be added after their position is ascertained from onboard observation. The cost of chafe patches is not included in the bid for the sail because the size, shape, and location of chafe patches cannot be standardized.

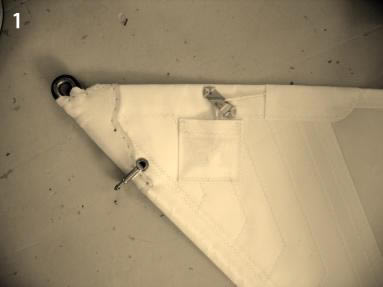

- Headboard with doubled slides, wrapped boltrope with leather chafe protection, hand-sewn ring, Strong Track with stainless steel luff slide

- Leathered tack

- Loose-foot, clew, Spectra/Velcro clew strop

- Classic full batten main (plus roller furling genoa and classic mizzen)

In-Mast Furling Mainsails

Your in-mast furling mainsail will be designed and constructed to be as durable and maintainable as possible within the constraints of the furler manufacturer’s sailmaking instructions. In addition to most of the details described under “All Sails”, your classic mainsail will have the following specific construction details:

- Cross cut

- UV Dacron runner on leech and foot for strength and UV protection while sail is furled

- Spectra webbing at head and tack.

- Antal clew block secured to sail with spectra webbing covered with UV protective material

- Leech line (if furling system allows)

- Leathered head and tack webbings (if furling system allows)

- Sunbrella UV cover

- Day and night (Glowfast) reef marks at 30% and 60%

- All edges are reinforced with two tapes

- Furling tape is custom measured and cut to preclude chafe

Areas of your mainsail that might get chafed by shrouds, spreaders, and other rigging cannot be precisely known until the sail is bent-on and marked. Any chafe patches must be added after their position is ascertained from onboard observation. The cost of chafe patches is not included in the bid for the sail because no size, shape, or location of chafe patches is standard. Chafe patches must be billed on a time and materials basis.

- In-mast furling main, Spectra head webbing

- Antal clew block, Sunbrella UV clew cover, leech and foot line pocket

- In mast furling mainsail (plus SpinDrifter—asymmetric spinnaker)

Roller Furling Headsails

Performance, versatility, durability, ease of handling, and ease of stowage are all important in the design and structure of our headsails. In addition to the construction details described under “All Sails” on the General Sail Construction Details document, your roller furling genoa will have the following specific construction details:

- Cross cut

- Spectra and Dacron webbing at head and tack

- Webbing overlaps furling tape at head and tack for load transfer

- Furling tape is custom measured and cut to preclude chafe

- Luff is reinforced with two edge tapes

- Three rows of tell-tales positioned so tell-tales are visible as sail gets furled

- Leech and foot runners for additional strength when reefed

Sunbrella UV Cover

- Wide enough to cover exposed Dacron

- Rolled leech and foot hems

- All corners covered on both sides

- No adhesive used

- Day and night (Glowfast) reef marks at 15% and 30%

Foam Luff

- Closed cell foam for better shape recovery over time

- Foam strips (not one solid piece) for more efficient furling

- Light weight Dacron over foam strips for flexibility in furling

- Foam strips are tapered into sail for optimal shape when furled

Areas of your genoa that might get chafed by shrouds, spreaders, and other rigging cannot be precisely known until the sail is bent-on and marked. Any chafe patches must be added after their position is ascertained from onboard observation. The cost of chafe patches is not included in the bid for the sail because no size, shape, or location of chafe patches is standard. Chafe patches must be billed on a time and materials basis.

- Layout of closed cell foam strips for luff support when sail is furled

- Clew details including leech and foot line exits with pockets, Sunbrella UV cover, leathered clew piece

- Roller furling genoa (plus standard batten mainsail with a top full batten)

Hanked-On Headsails

Performance, versatility, durability, ease of handling, and ease of stowage are all important in the design and structure of our headsails. In addition to the construction details described under “All Sails”, your hanked-on headsail will have the following specific construction details:

- Cross cut

- Reinforcement patches at hanks

- Bronze, hand-tied piston hanks with leather chafe protection

- Internal bolt rope served and seized at both ends

- Bolt rope tensioned to take load off sail cloth

- Cast bronze thimbles at head and tack

Areas of your headsail that might get chafed by shrouds, spreaders, and other rigging cannot be precisely known until the sail is bent-on and marked. Any chafe patches must be added after their position is ascertained from onboard observation. The cost of chafe patches is not included in the bid for the sail because no size, shape, or location of chafe patches is standard. Chafe patches must be billed on a time and materials basis.

- Tack thimble, leather chafe protection, hank, leech line cleat and pocket

- Hand-tied bronze piston hank

- Hanked on jib (plus mainsail)—fractional rig—Nordic Folkboat

- Sail loft crew hand-tying hanks on a jib

Storm Headsails

Your storm stays’l or storm jib is designed for use in combination with a reefed mainsail or a trys’l. It is cut and constructed with a size and shape to keep your boat moving forward or assist in heaving-to under extreme conditions. In addition to the construction details described under “All Sails”, your storm headsail will have the following specific construction details:

- Scotch cut

- Reinforcement patches at hanks

- Bronze, hand-tied piston hanks with leather chafe protection

- Internal bolt rope served and seized at both ends

- Bolt rope tensioned to take load off sail cloth

- Cast bronze thimbles at head and tack

- Leech runner

- Webbing reinforcement at foot

Visibility patch: We offer the option of a fluorescent yellow visibility patch. It is sewn on both sides of the storm jib, storm stays’l, or trys’l near the head of the sail. The visibility patch helps make your vessel distinguishable from white caps in the ocean and clouds on the horizon. We recommend this patch rather than a solid fluorescent sail because high quality premium Dacron is not available in fluorescent colors; therefore, the body of your sail should be constructed of the high quality white Dacron we use for all our working sails.

Tack pendant: Most storm headsails will require a tack pendant. Unless otherwise requested our spectra tack pendant will be integral to the tack thimble on one end and have a stainless steel snap shackle on the other end. The spectra webbing will be wrapped in a chafe and UV resistant material.

- Tack details including Spectra pendant with chafe protection, bronze tack thimble, leather, hand-tied bronze piston hank

- Flouro-yellow visibility patch

- Storm stays’l (plus trys’l)

Trys’ls

Your trys’l is cut and constructed with a size and shape to keep your boat moving forward or assist in heaving-to under extreme conditions. In addition to the construction details described under “All Sails”, your trys’l will have the following specific construction details:

- Vertical cut

- Visibility patch

- External boltrope on luff and foot

- Leech reinforced with webbing and a runner

- Slides doubled at head and tack

- Webbing strainers at head and tack

- Primary rings are stainless steel super rings

- Head details

- Hoisted trys’l

- Trys’l (plus storm stays’l)

SpinDrifter Asymmetric Cruising Spinnaker

Our asymmetric cruising spinnaker is a powerful sail that will add speed, versatility, safety, and enjoyment to your sailing experience. The addition of an ATN Spinnaker Sleeve and ATN Tacker (if your headstay has a furling system on it) makes our SpinDrifter easy to handle.

In addition to most of the details from the General Sail Construction Details document, your SpinDrifter will have the following specific construction details:

- Tri-radial cut

- All seams flat felled

- All seams stitched with triple-step/zig-zag

- Trim lines on all three sail edges

- Double taped luff

- Comes with a 3/8” Sta-Set downhaul line—of appropriate length for the size of your vessel and rig

- Custom artwork/inlay available—estimate provided on request

- SpinDrifter for Hess BCC including custom inlay

- ATN Spinnaker Sleeve in use on Crealock 37

- SpinDrifter on Crealock 37

Drifter

This lightweight and manageable genoa-style headsail will add light air performance and upwind ability to your sail inventory.

In addition to most of the details from the General Sail Construction Details document, your Drifter will have the following specific construction details:

- Cross-cut or tri-radial depending on your preference, the size of your boat, and the way the sail will be flown (hanked-on or free-flying)

- If the drifter is built of .75 or 1.5 ounce nylon, the seams will be flat felled and triple stepped

- If the drifter is built of 2.2 ounce nylon, panel edges will be burned (heat sealed) and seamed with two lines of stitching

- Internal luff rope served and seized around thimbles at head and tack

- Luff rope tensioned to take load off sail cloth

- Custom artwork/inlay available—estimate provided on request

If drifter is hanked-on:

- Reinforcement patches at hanks

- Hand-tied piston hanks with leather chafe protection

- Hand-sewn rings at head and tack with stainless steel Rutgerson rings along luff for piston hanks

- Hanked-on cross cut drifter with custom inlay/Jason 35 (photo credit: Bill Kramer)

- Hanked-on cross-cut drifter/Westsail 43

- Hand-tied piston hank on cross-cut drifter